Zhuzhou Xinpin Cemented Carbide Co., Ltd. is located in Zhuzhou City, Hunan Province. It is a high-tech enterprise specializing in R&D, production, and sales of high-quality cemented carbide materials. We have technical production engineers with more than 20 years of working experience, and professional marketing engineers and production management backbone teams.

Tungsten Carbide rectangle strips or flat blanks are usually used as very important accessories for woodworking knives. In order to meet the real-time changing pattern requirements of the market, tool manufacturers need to use wire cutting or grinding wheels to grind the standard carbide blanks into specific nonstandard shapes, and then weld them on the steel substrate of the woodworking cutter to finish the milling, grooving, planing works

Due to the long size of carbide blanks, the raw powder should be uniform during the pressing and forming process. We use a 315t overweight automatic pressing machine. After sintering, it must ensure there is no porosity inside, which is the most common cause of broken issues, We do the HIP sintering once again for all grades of tungsten carbide blanks to improve the crack-resistant quality. Due to the difficult complicated process of TCT woodworking cutters, like big welding areas 、simple welding, and grinding equipment, most TCT cutter makers, have strict demand for carbide strips with excellent crack resistance and good wear resistance. And following grades are popular accepted by the market

Grade chart recommended for tungsten carbide strips/blanks | |||||||

Grade | ISO CODE | Grain Size | Binder | Density(g/Cm3) | Hardness(HRA) | Transverse Rupture Strength(N/mm2) | Application recommended |

XF8 | K20 | Fine | 8 | 14.5-14.7 | 91.0-92.0 | ≥2800 | TCT wood cutter for cutting hardwood, laminated board and MDF HDF etc |

XF10 | K30 | Fine | 10 | 14.3-14.5 | 90.5-91.5 | ≥3000 | |

XK10 | K10 | Medium | 6 | 14.8-15.0 | 90.5-91.0 | ≥2400 | TCT wood cutter for cutting softwood, solid wood etc |

XK20 | K20 | Medium | 8 | 14.6-14.8 | 89.5-90.5 | ≥2600 | |

Tungsten Carbide mold sizes are available and customized sizes are also welcomed

Tungsten Carbide mold sizes are available and customized sizes are also welcomed

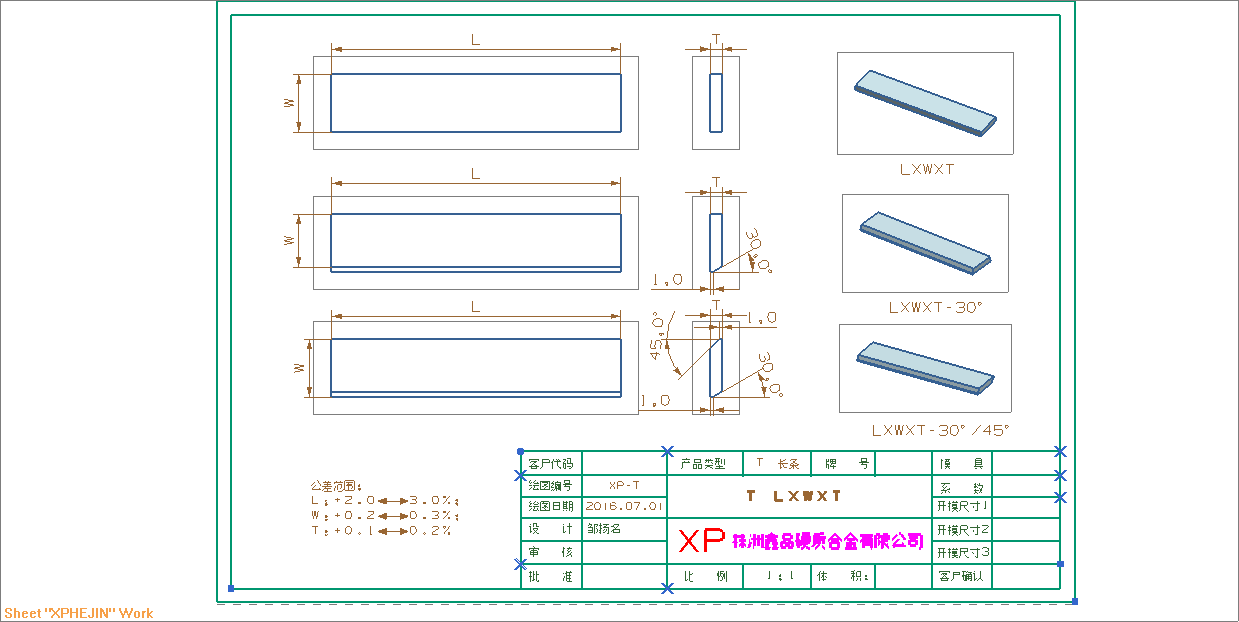

Rectangle and one side with a cutting edge angle of 30° and 2 sides with a cutting edge angle of 30°

Length from 330mm to 10mm

Length(mm) | Width (mm) | Thickness(mm ) |

330 | 6.0-40.0 | 2.0-6.0 |

320 | 6.0-40.0 | 2.0-6.0 |

310 | 6.0-40.0 | 2.0-6.0 |

300 | 6.0-40.0 | 2.0-6.0 |

150 | 6.0-70.0 | 2.0-6.0 |

200 | 6.0-70.0 | 2.0-6.0 |

Tolerance standard for blank unground surface

Tolerance of length (mm) | ||||

Length | ≤25 | >25-50 | >50-100 | >100 |

+0.50 -0.00 | +1.00 -0.00 | +2.00 -0.00 | +(Lx2%) -0.00 | |

Tolerance of width (mm) | |||||

Width | ≤10.0 | >10.0-20.0 | >20.0-30.0 | >30.0-40.0 | >40.0 |

+0.30 -0.00 | +0.40 -0.00 | +0.50 -0.00 | +0.60 -0.00 | +1.00 -0.00 | |

Thickness | ≤1.0 | >1.0-2.0 | >2.0-3.0 | >3.0 |

+0.2 -0.00 | +0.25 -0.00 | +0.25 -0.00 | +0.60 -0.00 | |

Tolerance of straightness | ||||

Length | ≤50.0 | >50-100 | >100-200 | >200 |

≦0.15 | ≦0.20 | ≦0.25 | ≦0.30 | |

Factory Tour

Why Choose Us

1. You can get the perfect material according to your requirement at the least possible price.

2. We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

3. The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

4. guarantee to give a response within 24hours(usually in the same hour)

5. You can get stock alternatives, mill deliveries with minimizing manufacturing time.

6. We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

Contact Us

For any questions, you're always welcome to contact with us!

Email: info@xpcarbide.com

Wechat/WhatsApp: +86 18873329727